المنتجات الساخنة

The extraction of tin (Sn) from primary tin ore deposits

网页2021年6月24日This research aims to observe the extraction of tin from primary deposits (oxide and skarn ores) using HCl wet chlorination, observed at different temperature (60 90°C), HCl concentrations (10 50 % excess of stoichiometric amount), leaching time

Contact

(PDF) The extraction of tin (Sn) from primary tin ore

网页2021年11月1日This research aims to observe the extraction of tin from primary deposits (oxide and skarn ores) using HCl wet chlorination, observed at different temperature (60

Contact

Tin processing Britannica

网页tin processing, preparation of the ore for use in various products. Tin (Sn) is a relatively soft and ductile metal with a silvery white colour. It has a density of 7.29 grams per cubic

Contact

12.3: Metals and Ores Chemistry LibreTexts

网页2022年8月10日Metal ores are generally oxides, sulfides, silicates (Table 12.3.1) or "native" metals (such as native copper) that are not commonly concentrated in the

Contact

Tin Ore Extraction 911 Metallurgist

网页2016年5月24日Tin Ore Extraction The flowsheet below Explains the Extraction of Tin Ore as shown by a study adapted to the concentration

Contact

Tin sources and trade in ancient times

网页Tin extraction and use can be dated to the beginning of the Bronze Age around 3000 BC, during which copper objects formed from polymetallic ores had different physical properties. The earliest bronze objects had tin or

Contact

THE EXTRACTION OF TIN FROM ITS ORES AND THE

网页EXTRACTION OF TIN FROM ITS ORES. 1. Occurrenc ofe Samples . Tin occurs Natur ine in three forms (1: ) as Cassiterite or stannic oxide (2, ) as stannite, the combined

Contact

EP0192334A1 Extraction of tin from its ores Google

网页According to the present invention, tin values are directly extracted from unrefined ores or slags as a compound of the formula R a SnX (4-a) wherein each R represents an organic

Contact

How to extraction tin from tin ores Mineral

网页2020年7月10日Extraction of tin from its ore generally adopts a gravity separation method, which is determined by the density of tin ore than the characteristics of paragenetic minerals. However, iron oxides such as

Contact

Extraction of Metals from Ores Different Processes

网页2023年5月4日The basic extraction of metals from ores has the following steps. Grinding and Crushing. The bigger chunks of the ore extracted are crushed and ground in ball

Contact

The extraction of tin (Sn) from primary tin ore deposits

网页2021年6月24日This research aims to observe the extraction of tin from primary deposits (oxide and skarn ores) using HCl wet chlorination, observed at different temperature (60 90°C), HCl concentrations (10 50 % excess of stoichiometric amount), leaching time (60 300 minutes), and with or without the addition of oxidant (hydrogen peroxide, H 2 O 2 ).

Contact

12.3: Metals and Ores Chemistry LibreTexts

网页2022年8月10日Metal ores are generally oxides, sulfides, silicates (Table 12.3.1) or "native" metals (such as native copper) that are not commonly concentrated in the Earth's crust, or "noble" metals (not usually forming compounds) such as gold (Figure 12.3.1 ). The ores must be processed to extract the metals of interest from the waste rock and from

Contact

Hydrometallurgical extraction of tin from cassiterite

网页In relation to the types of tin ores, oxidised or sulphide, the literature lists several industrial techniques for extracting tin based on the chemical composition of the ore to be processed (Habashi, 1997; Gostishchev, et al., 2008). These include pyrometallurgical and hydrometallurgical techniques.

Contact

THE EXTRACTION OF TIN FROM ITS ORES AND THE

网页THE EXTRACTION OF TIN FROM ITS ORES AND THE PREPARATION AND BEHAVIOR OF CERTAIN PURE SALTS OF TIN. INTRODUCTION. The existenc of isotopee s has explained a great many- discrepancies in the theory of atomic structure It. has also definitely settlethd evalidity of the whole number rule for the atomic weight ofs the elements.

Contact

Tin sources and trade in ancient times

网页Tin extraction and use can be dated to the beginning of the Bronze Age around 3000 BC, during which copper objects formed from polymetallic ores had different physical properties. The earliest bronze objects had tin or

Contact

Extraction of Tin From Its Ore JXSC Machine

网页Extraction of tin from its ore generally adopts gravity separation method, which is determined by the density of tin ore than the characteristics of paragenetic minerals. However, iron oxides such as magnetite and

Contact

Mining Wikipedia

网页The process of mining from discovery of an ore body through extraction of minerals and finally to returning the land to its natural state consists of several distinct steps. and 25% of global tin production. More than

Contact

April 10, 1951 C, R, HAYWARD ET AL EXTRACTION

网页The present invention relates to the extraction of tin from tin-bearing ore or concentrates con taining iron, and more particularly to a process for the reduction of tin oxides contained in such Ores or concentrates in a gaseous reducing mediuin. in the past, tin has been extracted from tin Ores, Such as cassiterite in which it is present as

Contact

Extraction of Metals from Ores Different Processes

网页2023年5月4日This is one of the methods of extraction of metals from ores by using two mediums together. Both oil and water are used to separate impurities. It can only be done when the ore forms froth when compressed air is passed in this medium. The frothed ore collects on the oil section whereas the impurities settle down in the water medium.

Contact

Tin Ore Extraction JXSC Mining

网页2022年3月30日Brief history of extracting tin from tin ores. In nature, the tin ore are existing in sand or alluvial raw material, this kind of tin ore is called sand tin or alluvial tin, those raw materials may be stone, sand, gravel, soil, sticky clay, some times with other magnetic iron, tungsten, ilmenite, hematite, monazite, zircon sand and other

Contact

Tin processing Mining and concentrating Britannica

网页There are two methods of refining impure tin. Fire refining is most commonly used and produces tin (up to 99.85 percent) suitable for general commercial use. Electrolytic refining is used on the products of complex ores and to produce a very high grade of tin (up to 99.999 percent). One fire-refining method is called boiling.

Contact

Chemistry of Titanium Chemistry LibreTexts

网页2020年8月21日Titanium Extraction. Titanium cannot be extracted by reducing the ore using carbon as a cheap reducing agent, like with iron. The problem is that titanium forms a carbide, \(\ce{TiC}\), if it is heated with carbon, so you don't get the pure metal that you need. The presence of the carbide makes the metal very brittle.

Contact

Tin Extraction Metalcess

网页Reduction smelting is the dominant process to extract tin metal from tin concentrate. Metalcess suggest electrical furnace for tin smelting because of its relatively low cost, short process and smart recycling of iron. Recommended Process: Extraction of Tin/ Stannum Crude Tin Refining Nickel-Cobalt Sulfide Ore Nickel Sulfide Ore Laterite-nickel ore

Contact

How to Start Extraction and Processing Business of Tin

网页2022年12月30日Once the ore has been procured, the next step is to extract the tin from the cassiterite ore. This can be done through a variety of methods, including physical separation, chemical...

Contact

Chemistry of Titanium Chemistry LibreTexts

网页2020年8月21日Both of these would, of course, first have to be extracted from their ores by expensive processes. The titanium is produced by reacting titanium (IV) chloride, TiCl 4 NOT the oxide with either sodium or magnesium. That means that you first have to convert the oxide into the chloride.

Contact

12.3: Metals and Ores Chemistry LibreTexts

网页2022年8月10日Metal ores are generally oxides, sulfides, silicates (Table 12.3.1) or "native" metals (such as native copper) that are not commonly concentrated in the Earth's crust, or "noble" metals (not usually forming compounds) such as gold (Figure 12.3.1 ). The ores must be processed to extract the metals of interest from the waste rock and from

Contact

Hydrometallurgical extraction of tin from cassiterite

网页In relation to the types of tin ores, oxidised or sulphide, the literature lists several industrial techniques for extracting tin based on the chemical composition of the ore to be processed (Habashi, 1997; Gostishchev, et al., 2008). These include pyrometallurgical and hydrometallurgical techniques.

Contact

Tin Price, Occurrence, Extraction and Use Institute for

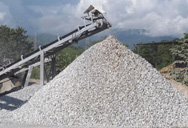

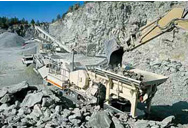

网页For the extraction of tin, the ore is first crushed and then enriched by various methods (slurrying, electrical / magnetic divorce). After reduction with carbon, the tin is heated just above its melting temperature so that it can flow away without higher melting impurities.

Contact

Tin sources and trade in ancient times

网页Tin extraction and use can be dated to the beginning of the Bronze Age around 3000 BC, during which copper objects formed from polymetallic ores had different physical properties. The earliest bronze objects had tin or

Contact

Mining Wikipedia

网页The process of mining from discovery of an ore body through extraction of minerals and finally to returning the land to its natural state consists of several distinct steps. and 25% of global tin production. More than

Contact

How to extraction tin from tin ores Mineral

网页2020年7月10日How to extraction tin from tin ores Mineral Processing In general, the rock tin ore processing is mainly by using gravity selection, together with crushing, grinding, flotation and other beneficiation

Contact

April 10, 1951 C, R, HAYWARD ET AL EXTRACTION

网页The present invention relates to the extraction of tin from tin-bearing ore or concentrates con taining iron, and more particularly to a process for the reduction of tin oxides contained in such Ores or concentrates in a gaseous reducing mediuin. in the past, tin has been extracted from tin Ores, Such as cassiterite in which it is present as

Contact

Extraction of Metals from Ores Different Processes

网页2023年5月4日This is one of the methods of extraction of metals from ores by using two mediums together. Both oil and water are used to separate impurities. It can only be done when the ore forms froth when compressed air is passed in this medium. The frothed ore collects on the oil section whereas the impurities settle down in the water medium.

Contact

Tin Ore Extraction JXSC Mining

网页2022年3月30日Tin ore extraction process flow Ore washing and desliming This step is aimed at raw materials with high mud content and strong cementation. Such raw materials must be washed and desliming before crushing. The mine washing machine is used for washing the ore, and the spiral classifier is used for the desliming and the hydrocyclone.

Contact

How do we extract minerals? U.S. Geological Survey

网页The primary methods used to extract minerals from the ground are: Underground miningSurface (open pit) miningPlacer mining The location and shape of the deposit, strength of the rock, ore grade, mining costs, and current market price of the commodity are some of the determining factors for selecting which mining method to use.Higher-grade

Contact

End of tin ore extraction Stock Photos and Images Alamy

网页Find the perfect end of tin ore extraction stock photo, image, vector, illustration or 360 image. Available for both RF and RM licensing.

Contact

Four Ways to Teach You How to Improve the Index of

网页2019年11月8日Before the extraction of tin ore, it is suggested that the ore owners should carry on the mineral processing test, and adopt the scientific and reasonable process for the extraction of tin ore

Contact

Tin (Sn) Ore Minerals, Occurrence, Formation, Deposits

网页Here is an overview of the typical process for tin ore mining and extraction: Exploration: The first step in tin ore mining is exploration, which involves identifying potential tin-bearing areas through geological surveys, geochemical analysis, and remote sensing techniques.

Contact