المنتجات الساخنة

Modelling and simulation of stamp-charged coke making

网页2013年11月1日A coal cake density of approximately 80% of the coal solid density is needed to produce a high-quality coke. Also, sufficient mechanical strength is required

Contact

Compacting of coals in cokemaking ScienceDirect

网页2019年1月1日The coal cake with slightly smaller dimensions than that of the oven is subsequently charged vertically standing into the oven on a coal cake charging plate

Contact

(PDF) A review on stamped charging of coals

网页2013年9月3日As is widely known, this process makes possible to obtain a coal cake with high density (up to 1080 kg/dm 3,dry base), as long as

Contact

Tailings solutions: How to filter down the options

网页The nature of the discharged cake will significantly impact the operation of the downstream material handling equipment. Sticky cakes will plug transfer chutes and stick to the

Contact

JP2008520774A Apparatus and method for horizontally

网页The present invention relates to an apparatus and method for horizontally producing a coal press cake for the purpose of carbonizing a coal cake in a coke oven furnace chamber,

Contact

(19) United States (12) Patent Application Publication

网页the tamped cakes is quoted as being 4-6m. 0006 For the production of low, i.e. horizontal, tamped coal cakes, such as are commonly used in so-called non recovery coke ovens,

Contact

5 Factors That Influence Filter Press Cake

网页2019年11月5日Many factors will determine how much liquid can be separated from a slurry to create a dewatered filter cake using a recessed/membrane plate Filter Press. Some of the primary factors

Contact

Horizontal vacuum belt filter HVBF Andritz

网页The horizontal vacuum belt filters by ANDRITZ offer numerous advantages for process plants: High-throughput dewatering and cake washing. Reduced downtime due to

Contact

coal cake English definition, grammar, pronunciation,

网页A process and device are disclosed for producing horizontally tamped coal cakes for coking in the oven chamber of a coking oven, the coal cakes being formed in a compression

Contact

Modelling and simulation of stamp-charged coke making

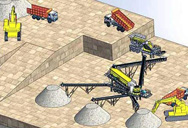

网页2013年11月1日In industrial scale, the final dimensions of the coal cake can be in the order of 16 m in length, 0.5 m width and up to 6 m in height. The coal cake is then transferred to the coke oven for carbonisation. The stamp-charged coke making machine is illustrated in Fig. 1. Download : Download full-size image Fig. 1.

Contact

Solid bowl centrifuge Wikipedia

网页Coal slurry, which contains around 6% solids by weight and nearly 60% of 10 mm material, is thickened using solid bowl centrifuges. By using this centrifuge technique, the concentration of the end product could reach up to 55

Contact

Compaction tests on coking coals. Part 2: Pilot-plant

网页coal, the transverse strength of the coal cake was relatively independent of the wet cake density. Since no compressive or transverse strength tests were performed during this study on 1 m3 coal cakes owing to some limitations of the pilot plant set-up at the time, the aim was to obtain coal cakes of a suitably wet cake density and stability.

Contact

A REVIEW ON STAMPED CHARGING OF COALS

网页A horizontal box is filled with the coal blend, with defined grain size distribution and moisture content, in three equal layers. Compaction and vibration is applied, through 24 plates covering...

Contact

Tailings solutions: How to filter down the options

网页The nature of the discharged cake will significantly impact the operation of the downstream material handling equipment. Sticky cakes will plug transfer chutes and stick to the conveyors. These problems can be mitigated by proper design of the entire system. Table 2: Comparison of Horizontal Belt Filters, Belt Presses, Centrifuge, and Filter

Contact

5 Factors That Influence Filter Press Cake

网页2019年11月5日Many factors will determine how much liquid can be separated from a slurry to create a dewatered filter cake using a recessed/membrane plate Filter Press. Some of the primary factors

Contact

(19) United States (12) Patent Application Publication

网页the tamped cakes is quoted as being 4-6m. 0006 For the production of low, i.e. horizontal, tamped coal cakes, such as are commonly used in so-called non recovery coke ovens, DE 19803 455 suggests that the cake be tamped in the known vertical press mould and the press mould be constructed as part of a tipping device in order to

Contact

Process and Device For Producing Horizontally Tamped

网页A process and device are disclosed for producing horizontally tamped coal cakes for coking in the oven chamber of a coking oven, the coal cakes being formed in a compression mould by stationary compression tools which work in the horizontal direction and with a stroke having a strictly limited length. The compression mould has a sliding stop wall which is

Contact

Process and Device for Producing Horizontally Tamped

网页Devices and processes for the tamping of coal cakes have been state of the art for a long time, for instance as described in DE 557 178 and DE 31 45 344. According to the state of the art, the tamped coal cakes are produced in a manner such that the cake grows in an upward direction up to its full height.

Contact

coal cake English to Portuguese Metallurgy / Casting

网页The combination of horizontal coal bed and the coal cake compaction method promote the formation of bigger, stronger coke. This site uses cookies. Some of these cookies are essential to the operation of the site, while others help to improve your experience by providing insights into how the site is being used.

Contact

(PDF) A Review on stamped charging of coals

网页2013年5月5日The process has been around since the early XX century. As an example, Coed Ely coke plant, in South Wales, UK, operated two batteries of 30 ovens each, built by Coppe Company in 1914, 34’ long, 8’...

Contact

Horizontal vacuum belt filter HVBF Andritz

网页The horizontal vacuum belt filters by ANDRITZ offer numerous advantages for process plants: High-throughput dewatering and cake washing. Reduced downtime due to innovative design. Global testing facilities. Increased flexibility due to modular design. Largest belt filter plant in the world consisting of 26 HVBF units each with 80 m² filter area.

Contact

Belt Filter an overview ScienceDirect Topics

网页As the cake moves through the belt filter, the gap between anode and cathode narrows, allowing to limit voids in the cake due to the water release. Coal Production, 2013. 13.5.4 Horizontal vacuum belt filter (HVBF) Huge areas of horizontal vacuum belt filters are installed for flotation coal dewatering as they provide ease in operation, a

Contact

US7815829B2 Process and device for producing

网页A process and device are disclosed for producing horizontally tamped coal cakes for coking in the oven chamber of a coking oven, the coal cakes being formed in a compression mold by stationary compression tools which work in the horizontal direction and with a stroke having a strictly limited length. The compression mold has a sliding stop wall which is

Contact

A Review on Stamped Charging of Coals

网页A horizontal box is filled with the coal blend, with defined grain size distribution and moisture content, in three equal layers. Compaction and vibration is applied, through 24 plates covering...

Contact

Compaction tests on coking coals. Part 2: Pilot-plant

网页coal, the transverse strength of the coal cake was relatively independent of the wet cake density. Since no compressive or transverse strength tests were performed during this study on 1 m3 coal cakes owing to some limitations of the pilot plant set-up at the time, the aim was to obtain coal cakes of a suitably wet cake density and stability.

Contact

A REVIEW ON STAMPED CHARGING OF COALS

网页A horizontal box is filled with the coal blend, with defined grain size distribution and moisture content, in three equal layers. Compaction and vibration is applied, through 24 plates covering...

Contact

(19) United States (12) Patent Application Publication

网页the tamped cakes is quoted as being 4-6m. 0006 For the production of low, i.e. horizontal, tamped coal cakes, such as are commonly used in so-called non recovery coke ovens, DE 19803 455 suggests that the cake be tamped in the known vertical press mould and the press mould be constructed as part of a tipping device in order to

Contact

Process and Device for Producing Horizontally Tamped

网页Devices and processes for the tamping of coal cakes have been state of the art for a long time, for instance as described in DE 557 178 and DE 31 45 344. According to the state of the art, the tamped coal cakes are produced in a manner such that the cake grows in an upward direction up to its full height.

Contact

5 Factors That Influence Filter Press Cake

网页2019年11月5日For example, coal particles tend to repel water and therefore are more easily dewatered to lower percent moistures. Dewatered filter cake from coal tailings. On the other hand, clay particles tend to be

Contact

Belt Filter an overview ScienceDirect Topics

网页As the cake moves through the belt filter, the gap between anode and cathode narrows, allowing to limit voids in the cake due to the water release. Coal Production, 2013. 13.5.4 Horizontal vacuum belt filter (HVBF) Huge areas of horizontal vacuum belt filters are installed for flotation coal dewatering as they provide ease in operation, a

Contact

Horizontal vacuum belt filter HVBF Andritz

网页This is why ANDRITZ has put decades of expertise into the Horizontal Vacuum Belt Filter (HVBF) technology, to provide a solution with the highest throughput and low residual cake moisture content, while keeping operating costs low. A cost effective solution for dewatering and product recovery

Contact

coal cake English to Portuguese Metallurgy / Casting

网页The combination of horizontal coal bed and the coal cake compaction method promote the formation of bigger, stronger coke. This site uses cookies. Some of these cookies are essential to the operation of the site, while others help to improve your experience by providing insights into how the site is being used.

Contact

horizontal coal cake GitHub

网页Contribute to jidafang2022/en development by creating an account on GitHub.

Contact

Compaction tests on coking coals. Part 2: Pilot-plant-scale

网页Introduction. Operation of the stamp-charging horizontal 1 t electrically heated coke pilot-plant oven at Exxaro Resources requires coal cake stability during the loading of a 1 m 3 compacted coal cake into the oven. In this case, a pusher plate is utilized to push the coal cake into the oven over the oven floor.

Contact

Nonrecovery and Heat recovery cokemaking technology

网页2019年1月1日The coal cake density of about or greater than 1100 kg/m 3 is achieved with approximately 8%–10% moisture. Kuyumcu and Sander (2014) indicated that stamp ability (densification) depends on coal rank, ash content, and particle size and developed an equation to predict stamp ability and also a methodology to predict cake stability for a

Contact

Compaction Tests on Coking Coals. Part 1: Laboratory

网页For Oaky North hard coking coal, a wet cake density of 1 189 kg/m3 (85% of 1 400 kg/m3 relative density) was achieved at a surface moisture content of 12.3% and at a lower applied force than that for Waterberg sscc, i.e. 78.5 t/m2.Coal cakes of acceptable strength, and therefore sufficient stability for further processing, were obtained for all

Contact

Process and Device For Producing Horizontally Tamped

网页A process and device are disclosed for producing horizontally tamped coal cakes for coking in the oven chamber of a coking oven, the coal cakes being formed in a compression mould by stationary compression tools which work in the horizontal direction and with a stroke having a strictly limited length. The compression mould has a sliding stop

Contact