المنتجات الساخنة

Prototype of a hammermill machine.

网页Figure 7 is the hammer. There are 16 all together and each is bolted to Figure 8. The rotor disc is welded to the shaft that transfers force for crushing. Figure 9 is the screen or sieve that...

Contact

(PDF) DESIGN AND EVALUATE OF A SMALL

网页2015年12月18日An H (m, g, k, 3) design is a triple (X, T, B), where X is a set of mg points, T a partition of X into M disjoint sets of size g, and B a

Contact

Hammer Mill HM 200: For LaboratoryPilot

网页This diagram shows a comparison of the Hammer Mill HM 200 with two rotor mills. The extremely high sample throughput of the HM 200 is clearly visible. The HM 200 shows a good crushing efficiency of 125, which is

Contact

Back to Basics Hammer Milling and Jet Milling

网页The hammer mill (Figure 1) is the most popular mechan- ical impact mill and is often used for general-purpose grinding. It is comprised of a rotating shaft fitted with freely swinging hammers mounted in a cage. Inside the cage is a breaker plate, against which the feed is disintegrated, chiefly by the impact from the hammers.

Contact

Prototype of a hammermill machine.

网页Figure 7 is the hammer. There are 16 all together and each is bolted to Figure 8. The rotor disc is welded to the shaft that transfers force for crushing. Figure 9 is the screen or sieve that...

Contact

All you need to know about The Hammer Mill Machine

网页2023年2月18日Schematic diagram of hammer mill machine The hammer mill consists of 1. Feed Chute Material is fed into the machine through a feed chute. 2. Discharge chute The crushed material leaves the machine through the discharge chute. 3. Hammer Hammer is used to break the material using impact.

Contact

Design and Evaluation of Crushing Hammer

网页2019年1月1日A grain size reduction hammer mill for crushing corn (Zea mays L.) was designed depending on variety characteristics and by using computer aided design “ANSYS” software. Suitability of

Contact

13 Practical Machining Projects for

网页1/4-20 x 2″ long hex bolt (x2) make sure to machine a half dog point on the tip so it doesn’t get stuck in the clamp Here are the drawings: VEE BLOCKS Download Edge Clamps This is a handy little set of clamps to

Contact

Design and Fabrication Of Hammer Mill

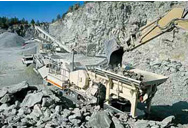

网页The PC hammer crush (hammer mill) was developed for both dry and wet crushing of brittle,medium-hard materials for the mining, cement, coal, metallurgic, construction material, road building, and petroleum and

Contact

Hammer Mill Working Principle

网页2020年4月16日A Hammer Mill is a machine whose sole purpose is to crush and aggregate materials into smaller particles. It does so by subjecting the material into a series of repeated blows. Hammer Mill grinder is the

Contact

Hammer Mill CrusherGrinder 911

网页2016年2月25日The hammermill, fundamentally, is a simple mechanism. The “orthodox” machine comprises a box-like frame, or housing, a centrally disposed, horizontal-shaft rotating element (rotor) on which the hammers

Contact

Hammer Mills for Particle Size Reduction

网页The diagram below illustrates the placement of a hammer mill in a typical pelletizing process where the hammer mill is used in the breakdown of oversize pellets. In certain low-energy impact situations where the

Contact

Hammer Mill || Principle, Construction,

网页A hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little hammers. These machines hav...

Contact

Impact Crusher an overview ScienceDirect Topics

网页For coarser crushing, the fixed hammer impact mill is often used (Figure 6.24). In these machines the material falls tangentially onto a rotor, running at 250–500 rpm, receiving a glancing impulse, which sends it spinning toward the impact plates. The velocity imparted is deliberately restricted to a fraction of the velocity of the rotor to

Contact

Tests of the innovative construction of the grain hammer

网页The performance of a hammer mill fabricated in Uganda was evaluated and the optimal performance conditions were determined. The evaluation was done with screen hole diameters (S) of 1.5, 2.0, and 3.0 mm, hammer tip speeds (H) of 68.12, 81.81, 102.17 m s and hammer thicknesses (T) of 4.0, 5.0, and 6.0 mm for determination of energy

Contact

Diagram Of A Typical Hammer Mill Machine Facty

网页Diagram Of A Typical Hammer Mill Machine. A hammer mill is typically good for grinding softer materials with Mohs hard-ness ranging from 1 to 5 while a jet mill can grind materials with Mohs hardness as high as 10. High hardness materi-als become very abrasive; therefore they are not suitable for high-speed hammer mills.

Contact

Hammer Mill HM 200: For LaboratoryPilot

网页This diagram shows a comparison of the Hammer Mill HM 200 with two rotor mills. The extremely high sample throughput of the HM 200 is clearly visible. The HM 200 shows a good crushing efficiency of 125, which is

Contact

Prototype of a hammermill machine.

网页Figure 7 is the hammer. There are 16 all together and each is bolted to Figure 8. The rotor disc is welded to the shaft that transfers force for crushing. Figure 9 is the screen or sieve that...

Contact

Design and Evaluation of Crushing Hammer

网页2019年1月1日A grain size reduction hammer mill for crushing corn (Zea mays L.) was designed depending on variety characteristics and by using computer aided design “ANSYS” software. Suitability of

Contact

Hammer Mills for Particle Size Reduction

网页The diagram below illustrates the placement of a hammer mill in a typical pelletizing process where the hammer mill is used in the breakdown of oversize pellets. In certain low-energy impact situations where the

Contact

13 Practical Machining Projects for

网页1/4-20 x 2″ long hex bolt (x2) make sure to machine a half dog point on the tip so it doesn’t get stuck in the clamp Here are the drawings: VEE BLOCKS Download Edge Clamps This is a handy little set of clamps to

Contact

Hammer Mill || Principle, Construction, workingUses

网页2020年9月12日A hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little hammers. These machines hav...

Contact

Conventional hammermill with semi

网页The detailed design procedure for a hammer mill machine is presented. The system designed is a modification to the conventional hammer mill with a circular bottom casing and a semi-circular screen.

Contact

Hammer Mill Working Principle

网页2020年4月16日A Hammer Mill is a machine whose sole purpose is to crush and aggregate materials into smaller particles. It does so by subjecting the material into a series of repeated blows. Hammer Mill grinder is the

Contact

Orthographic view and isometric view of

网页The detailed design procedure for a hammer mill machine is presented. The system designed is a modification to the conventional hammer mill with a circular bottom casing and a...

Contact

DEVELOPMENT OF A HORIZONTAL SHAFT

网页2019年12月23日A hammer mill has been designed with due considerations to standard design requirements and cost to cater to this need. The power required to deliver the through put efficiency of the

Contact

Hammermill Wikipedia

网页A hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little hammers. These machines have numerous industrial applications, including: Ethanol plants (grains) A farm machine, which mills grain into coarse to be fed to livestock. Fluff pulp defiberizing.

Contact

Design, construction and performance

网页2018年7月19日The hammer mill is a power mill making use of a high-speed rotating disc, which is stationary to a number of hammer bars that move superficially by a centrifugal force. The machine was made

Contact

Hosokawa Hammer Mill Demonstration

网页The Hosokawa Mikro Pulverizer® Hammer and Screen Mill is one of the most versatile and durable systems for fine size reduction down to D 97 = 45 µm. This bri...

Contact

Impact Crusher an overview ScienceDirect Topics

网页Diagrams to illustrate the basic actions of some types of crusher: solid shading highlights the hardened wear-resistant elements. (A) Single-toggle jaw crusher, (B) disc or gyrosphere crusher, (C) gyratory crusher and (D) impact crusher. (Modified from Murdock LJ, Brook KM. Concrete materials and practice. 5th ed. London, UK: Edward Arnold; 1979.)

Contact